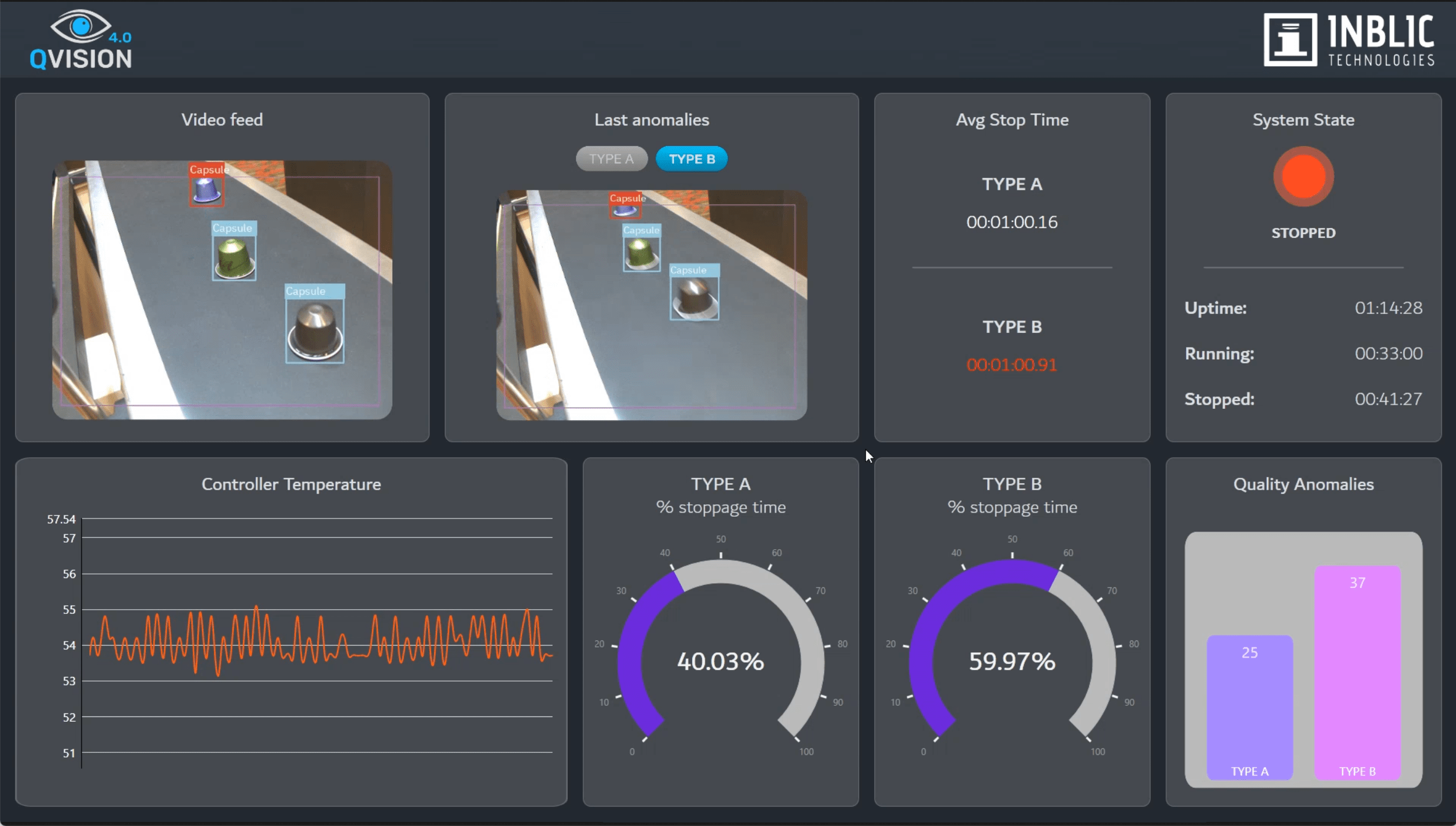

QVision: Quality Control

Challenge: Products produced with quality control issues such as coloring defects and human operator not being able to verify every product on the conveyor belt.

Solution:

Inblic Technologies developed an end-to-end solution which uses Machine Vision algorithms and Deep Learning models to scan products for quality control issues as they pass through a conveyor belt. Once a quality issue has been identified, the control loop is halted until the system senses that the defective product has been taken out of the loop.

Additionally, Inblic Technologies’ solution enables the human operator to visualize real-time relevant process data such as conveyor belt status, controller temperature, number and type of product defects, total product line downtime by defect, etc.

Technologies used: Automation, Machine Vision, Deep Learning, Cloud Computing, IoT, closed loop control.

Use Cases: Real-time visibility from process data and computer vision. Real-time OEE visibility. Data acquisition. Quality Control.

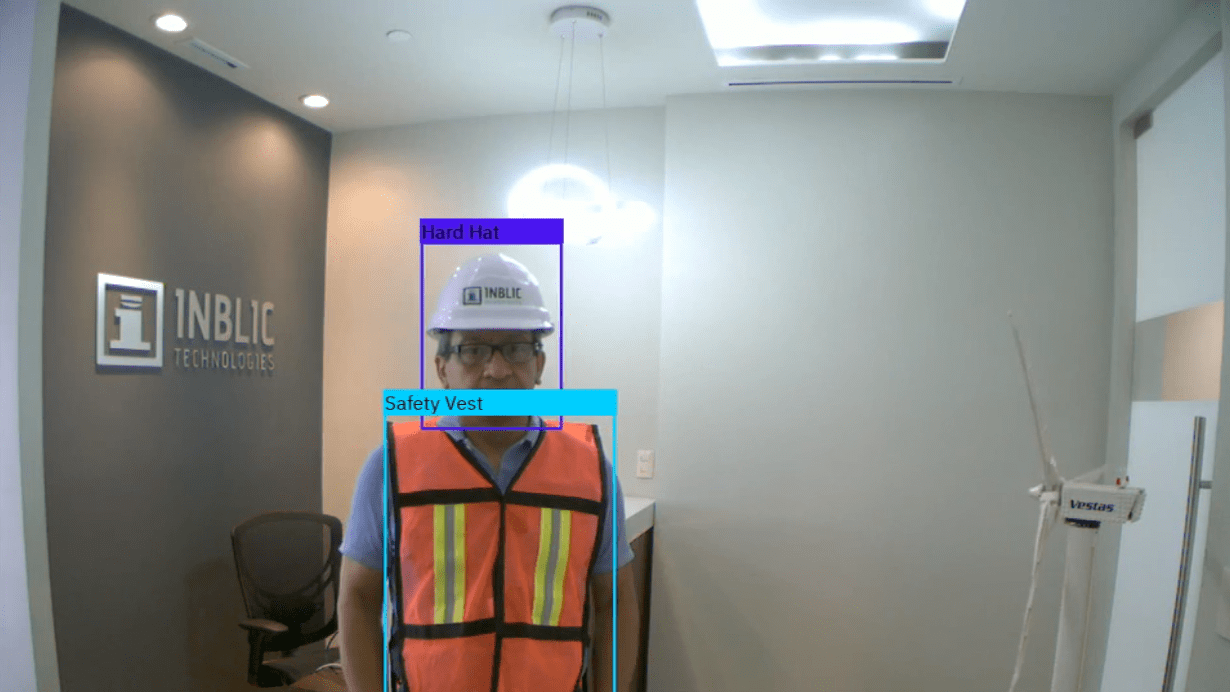

Industrial Safety: PPE Detection

Challenge: Personnel needs to have specific personal protective equipment (PPE) in order to use an industrial asset.

Solution: Inblic Technologies developed a solution which uses Machine Vision algorithms and Deep Learning models to detect if an operator is wearing the appropriate PPE (hard hat and safety vest) within the vicinity of the sensitive industrial asset (like a wind turbine). If the system senses that some part of the operator’s required PPE is missing, the industrial asset is halted and an alarm (LED light) is triggered.

Technologies used: Automation, Machine Vision, Deep Learning, Cloud Computing, IoT, closed loop control. Geofencing.

Use Cases: Industrial Safety PPE Detection. 5s-Housekeeping. Inventory verification. Data acquisition.

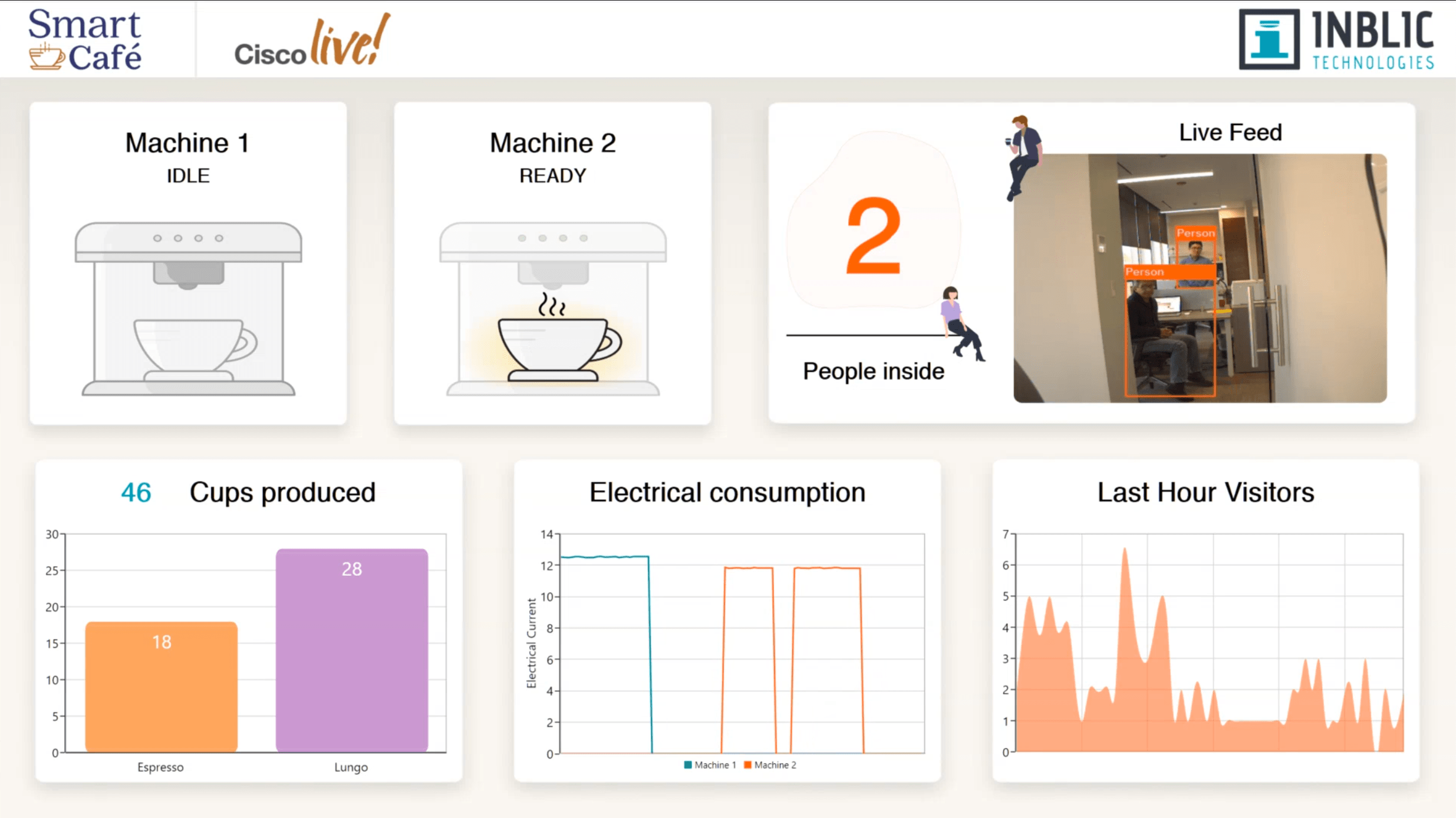

Smart Café

Challenge: Data is a powerful indicator of a business’ performance. However, smaller scale businesses such as coffee shops often don’t have access to real-time statistics of their operational data (such as number of visitors, coffees made, status of coffee makers, etc).

Solution:

Inblic Technologies developed a solution using IoT sensors on standard coffee makers, industrial cameras and machine vision algorithms to gather all the relevant insights that could be useful for the coffee shop. Our solution presents all of these insights in a dashboard that shows coffee maker energy usage, number of visitors in the shop, type and number of coffees produced, status of each coffee maker, and many more.

By having access to this data, the shop’s owners can optimize their expenses as they learn which types of coffee are more popular, at what time of day the shop is busiest, which employees are most productive, etc.

Technologies used: Automation, Machine Vision, Deep Learning, Cloud Computing, IoT.

Use Cases: Real-time visibility from process data and computer vision. Real-time OEE visibility. Data acquisition from legacy assets. Energy Management.